Niobium

About Niobium

Niobium is mainly used as an alloying element in steels to improve the strength of smaller, lighter components – particularly in the transport sector – where better fuel efficiencies and lower carbon dioxide emissions result.

Product information: niobium

Ferro-niobium will be produced and supplied as crushed ingots at a basic composition of 65%Nb, with two or three different specifications around natural alloying impurities produced to meet market demand.

Infrastructure

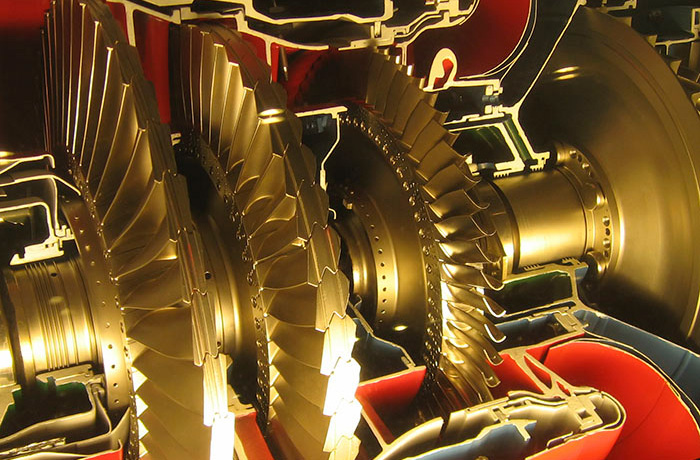

Power stations rely on niobium stainless steel turbine blades, which offer strength and corrosion resistance at extreme temperatures and pressures. For the same reason, pipelines for water, gas, oil and chemicals are often made from niobium stainless steels.

Superconductors

Superconductors containing niobium are used in a variety of applications – including Maglev trains, which travel at speeds of up to 430kph along a magnetic guideway, and Magnetic Resonance Imaging (MRI) for scanning medical patients.

Transport

High-strength low-alloy (HSLA) steels containing niobium offer high strength to weight ratios in vehicles, helping to reduce overall weight and improve fuel efficiencies and reduce emissions. Just 300g of niobium reduces the amount of steel used in a mid-sized car by 200kg and improves fuel efficiency by one litre per 200km driven.

Aerospace

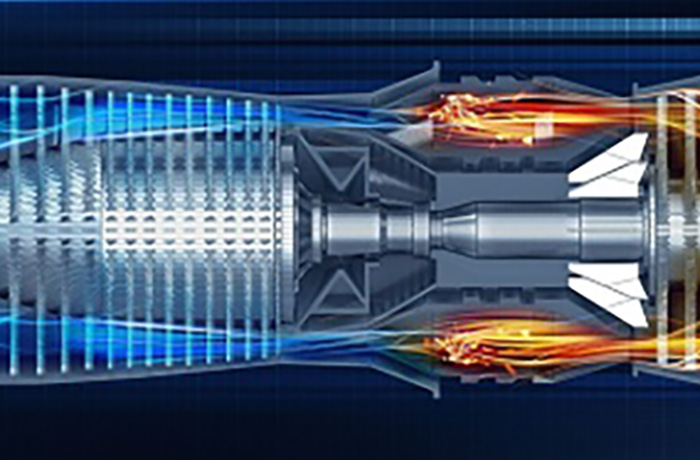

Niobium alloys are being used in aerospace rocket engine nozzles (with hafnium), jet engines and the newest generation of helicopters to improve strength to weight ratio, particularly at extreme temperatures and pressures.

Clean energy

Steels containing niobium are used to connect solid oxide fuel cells as they offer a combination of good formability and high electrical conductivity, corrosion resistance and mechanical strength at high temperatures.

Construction

Niobium hardens steels for greater strength at lower weight and cost for building infrastructure.

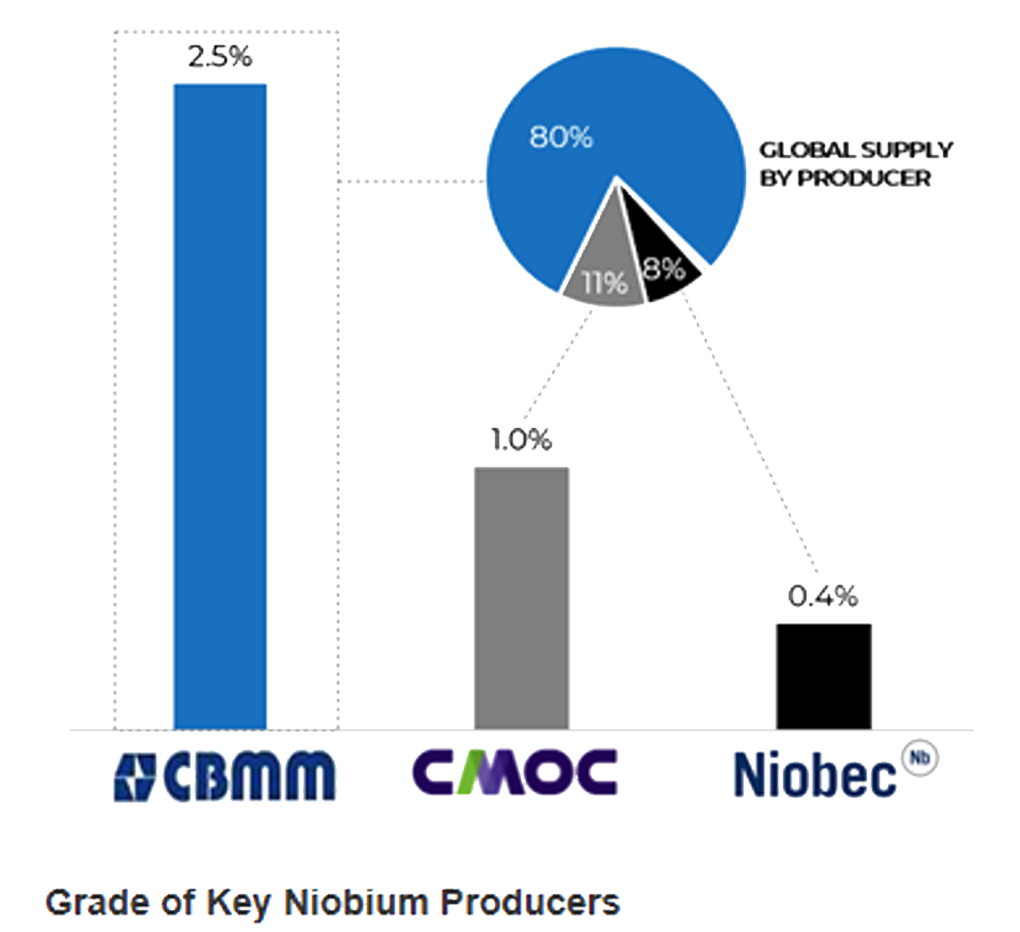

Niobium: Global resources & supply

The niobium market is dominated by (CBMM) and other smaller players with heavy reliance on Brazil, with CBMM and CMOC accounting for approximately 95% of global niobium supply and production and poses a significant supply risk for downstream users.¹

¹ Sector Research Niobium, 26th June 2023, Argonaut and https://www.wa1.com.au/

Niobium: Critical for advanced technologies

- Niobium is identified by the Australian Government and many other countries as a critical mineral

- Supply constrained with 10% penetration into global steel production as a micro alloy (<1%), ferroniobium (~$45,000/t¹) in various steel products can:

- Increase strength

- Reduce weight

- Increase corrosion resistance

- Increase heat resistance

- Important for infrastructure, gas pipeline and wind turbine construction

- Superconductor at low temperatures

- The addition of niobium to lithium-ion batteries overcomes some of the key hurdles to EV adoption²

- More stable and up to 20x faster charging

- Retains 80% capacity after 3,000+ cycles

¹ https://www.metalary.com/niobium-price/ accessed on 25 October 2022

² https://niobium.tech/Pages/Gateway-Pages/PDF/Briefings/Niobium_in_Li-Ion_Batteries accessed on 25 October 2022

³ https://batterystreak.com/tech/

Formula E – CBMM Niobium Puebla E-Prix²